Procesul de fabricație al canapelelor din piele

2025-11-25 12:46

The Manufacturing Process of Leather Sofas

The manufacturing process of leather sofas can be divided into two main parts: leather processing and sofa assembly. The specific process is as follows:

Leather Processing:

--Basic Treatment: Cowhide requires 20 processes, including soaking, liming, degreasing, and splitting, to --ensure the leather's chemical stability and physical properties.

--Tanning and Dyeing: Tanning stops organic decomposition; retanning determines the final feel; after dyeing, lubricant is applied and the leather is dried.

--Finishing: This includes hand polishing, ironing, and embossing to improve the leather's durability and appearance.

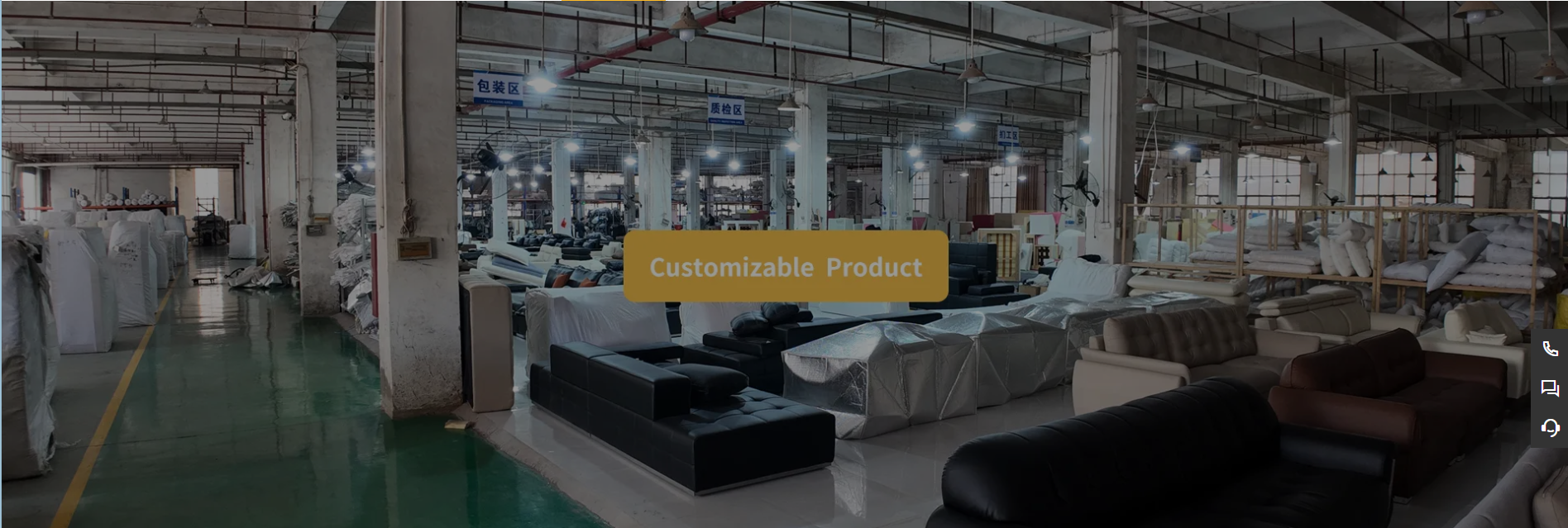

Sofa Assembly Process:

Frame Fabrication:

1. Use a CNC engraving machine to cut MDF or timber. The main keel needs to be reinforced with thick timber to ensure a sturdy structure.

2. Apply white glue to the frame joints and secure with straight nails to prevent later collapse.

Filling and Covering:

1. Sponge is cut to size and fixed with glue. Leather pieces are sewn by a seamstress and finally fitted onto the frame for secure binding.

2. Modern processes omit the traditional spring process, replacing it with elastic bands and PP cotton to improve comfort.

Classification and Materials:

--Full Leather Sofa: Uses genuine leather throughout, offering good breathability but at a high cost.

--Partial Leather Sofa: Genuine leather on the contact surfaces, artificial leather on other parts.

--Filling Materials: Traditionally, palm fiber was used; modern manufacturers often use sponge or polystyrene granules, which are lightweight and easy to shape.

Production Process:

--Frame Construction

1. Woodworking: Use a CNC engraving machine to cut wooden blocks to create the sofa frame. Key joints need to be fixed with F30 straight nails and reinforced with white latex to prevent later collapse.

2. Spring Installation: Evenly lay spring supports on the wooden frame base to ensure support.

--Filling and Covering

1. Sponge Cutting: Cut high-density sponge to the design dimensions, spray with adhesive, and attach it to the frame.

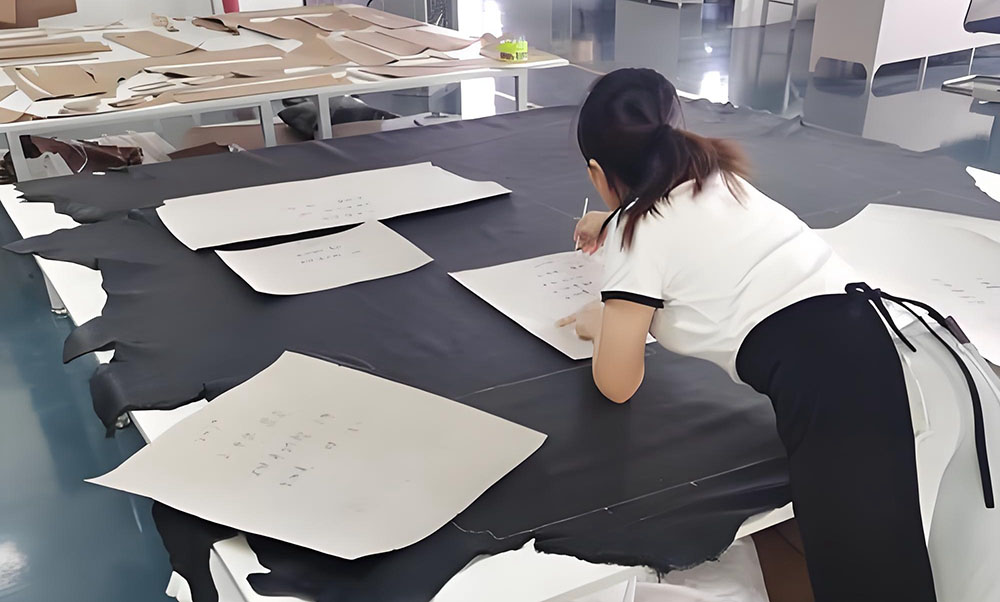

2. Leather Stitching: Genuine leather undergoes 20 processes (such as tanning and dyeing), is cut into leather covers, and sewn. Finally, it is fitted into the frame and secured with a retaining ring.

Detail Finishing:

1. Pleating: Use tools to press the leather seams to simulate the natural pleats of a leather sofa.

2. Functional Accessories: If it is a functional sofa, an electric support frame and movable parts need to be installed.